Difference between revisions of "AB-1386~U"

RadioNerds (talk | contribs) |

RadioNerds (talk | contribs) |

||

| Line 9: | Line 9: | ||

| − | == | + | ===Common problems=== |

| − | + | ===Frozen Bearing=== | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | ===Bearing | ||

[[File:AB1386_GEARBOX_1278.JPG|thumb|right|Gearbox with Old Bearing]] | [[File:AB1386_GEARBOX_1278.JPG|thumb|right|Gearbox with Old Bearing]] | ||

[[File:AB1386_GEARBOX_1283.JPG|thumb|right|Gearbox with New Bearing]] | [[File:AB1386_GEARBOX_1283.JPG|thumb|right|Gearbox with New Bearing]] | ||

| Line 30: | Line 25: | ||

# Once this is cut off you can press this into the new bearing and re-install it. | # Once this is cut off you can press this into the new bearing and re-install it. | ||

| − | [[File:AB1386_GEARBOX_1280.JPG| | + | [[File:AB1386_GEARBOX_1280.JPG|thumb|right|Pressing new bearing onto the aluminum backing]] |

===box turns, but wont raise or lower the tower=== | ===box turns, but wont raise or lower the tower=== | ||

| − | this is usually due to the | + | this is usually due to the output shaft notch no longer being tight. When the crank shaft is turned, this also turns and wont turn the large screw on the tower. |

I attempted to resolve this many ways, | I attempted to resolve this many ways, | ||

| Line 39: | Line 34: | ||

I tried.. | I tried.. | ||

| − | + | # dimpling the edge to make it tight | |

| − | + | # jb weld | |

| − | + | # wedging it from the back | |

| − | |||

| − | |||

Welding was the only one that worked. What you dont want, which i was privileged enough to experience, is to get the tower up, then have this loosen up again, and have no way to lower it. Weld it, you don't want this problem.. trust me. | Welding was the only one that worked. What you dont want, which i was privileged enough to experience, is to get the tower up, then have this loosen up again, and have no way to lower it. Weld it, you don't want this problem.. trust me. | ||

[[File:AB1386_GEARBOX_1271.JPG|thumb|left|Arrows pointing to new welds]] | [[File:AB1386_GEARBOX_1271.JPG|thumb|left|Arrows pointing to new welds]] | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

=Gear Box Images= | =Gear Box Images= | ||

Revision as of 01:01, 27 September 2012

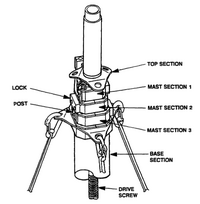

MAST AB-1386/U - NSN 5985-01-381-6341

Total mast height is variable from 8.3 to 33.1 ft (2.5 to 10.1 m) with all mast sections fully deployed. Accessories are provided to assist with guying, anchoring, and operating the mast in its ground mount configuration. They include a hammer, a tripod, guy assemblies, guy stakes, baseplate stakes, crank handle, baseplate, and a radius rope.

Two mounting kits may be used to adapt the HMMWV and the tracked vehicle with brackets and hardware to deploy the mast. The mounting kits are used to anchor the mast to the vehicle and to stabilize the mast when deploying it under normal conditions (i.e., winds below 25 mph [40 kph]).

Contents

Common problems

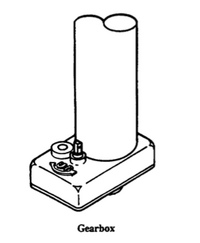

Frozen Bearing

Upon removal there is a large bearing, I had to replace this, as mine was frozen up. the proper replacement bearing is a Koyo #62052RDC3. You will need a press to do this..

- Remove the bearing from the housing

- Lightly tap the bearing while holding the outer ring to remove it (the one with the notch)

- Place the bearing in the press or suitable jig, and knock the brass bushing out from the rear.

- Remove the aluminum backing is attached to the bearing in the center, this wasn't meant to be re-used, so you will have to cut the bearing from around it. I tried using different pullers, but the aluminum will bend and deform, before the bearing is removed.

- Once this is cut off you can press this into the new bearing and re-install it.

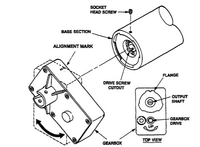

box turns, but wont raise or lower the tower

this is usually due to the output shaft notch no longer being tight. When the crank shaft is turned, this also turns and wont turn the large screw on the tower.

I attempted to resolve this many ways,

I tried..

- dimpling the edge to make it tight

- jb weld

- wedging it from the back

Welding was the only one that worked. What you dont want, which i was privileged enough to experience, is to get the tower up, then have this loosen up again, and have no way to lower it. Weld it, you don't want this problem.. trust me.

Gear Box Images

Additional Files

- OPERATOR'S AND UNIT MAINTENANCE MANUAL INCLUDING REPAIR PARTS AND SPECIAL TOOLS LIST EQUIPMENT DATA

- MAST AB-1386/U (NSN 5985-01-381-6341) (EIC:N/A)

- OPERATOR PMCS WITH ELECTRICAL EQUIPMENT MOUNTING MT-6967/G (NSN MT-6968/G (NSN 5975-01-390-9612) (EIC: N/A)